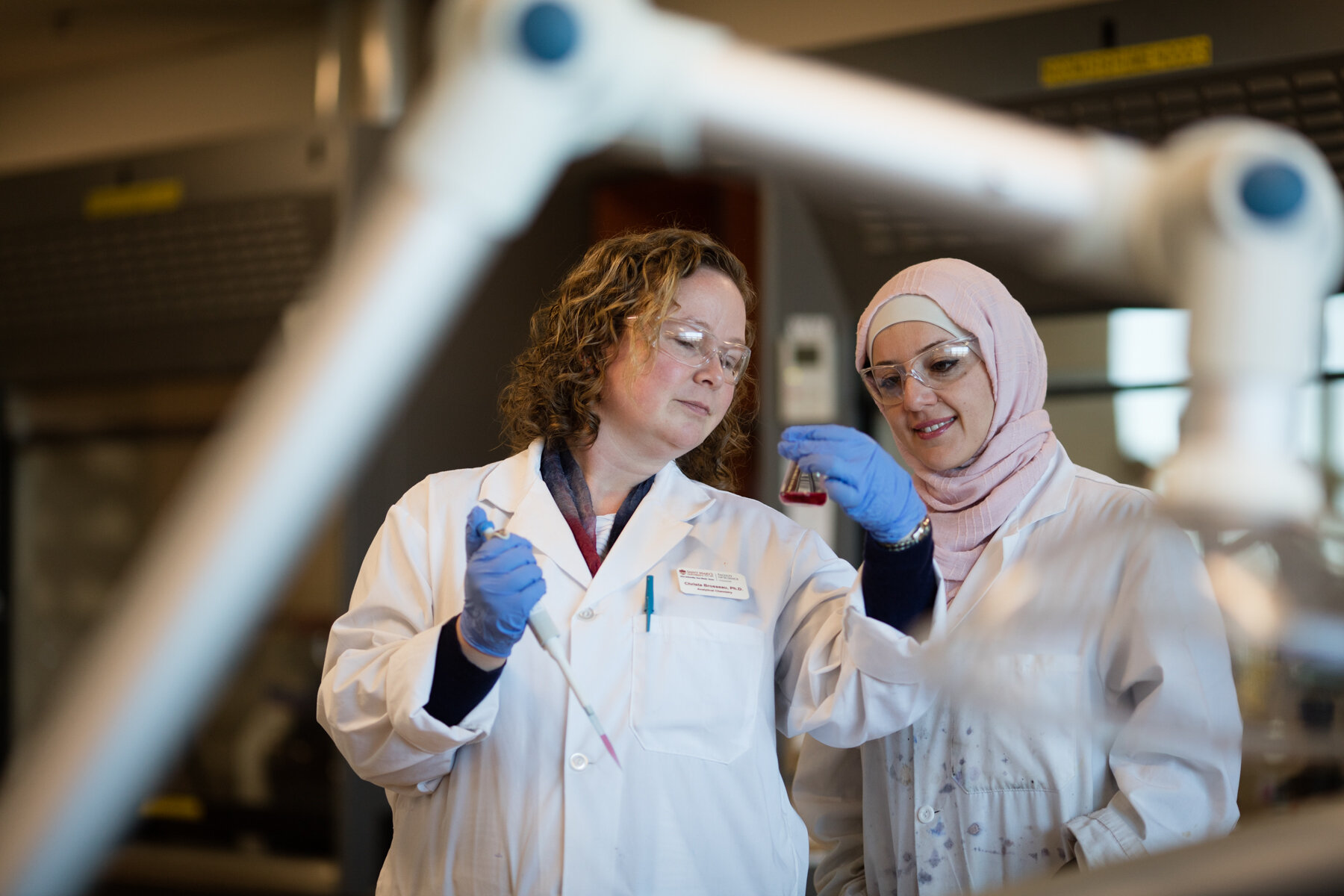

Dr. Christa Brosseau (left)

A Saint Mary’s University researcher is leading a project to help address a key support needed for the COVID-19 pandemic: personal protective equipment and their components.

“As a result of COVID-19, there is a massively increased global demand for N95 respirators,” says Dr. Christa Brosseau. “New technologies are urgently needed to help manage impending shortages, ideally with ’home-grown’ solutions.”

Dr. Christa Brosseau is a professor in Saint Mary’s University’s Faculty of Science and Canada Research Chair in Sustainable Chemistry & Materials. Her project will explore innovative chemical strategies to help determine if Nova Scotian pulp mills can produce medical-grade pulp for N95 respirator production. A recent grant from Research Nova Scotia will help propel this work forward.

N95 masks are typically composed primarily of synthetic polymer materials (polypropylene, polyester) with cellulose sometimes incorporated into one of the many layers that make up the respirator. At present, a single mill in Canada is producing medical grade pulp and they are struggling to keep up with the increased demand.

“Over the years, there has been an increased interest in making N95 respirators using only wood pulp”, says Dr. Brosseau. “However, wood pulp typically lacks certain properties that translate into effective respirator material.”

Dr. Brosseau’s team, in collaboration with the pulp and paper industry in Nova Scotia, will develop and test chemical additives that can address key challenges in the production of medical-grade pulp from thermomechanical pulp. Using combined expertise in the areas of chemical synthesis, materials characterization and process development, they will work towards an innovative “made-in-Nova Scotia” approach for creation of a product similar to the Western red cedar formulation currently produced in British Columbia.

If successful, this project could help meet the needs of frontline healthcare workers by supplying adequate PPE protection from COVID-19 while also supporting the Nova Scotian pulp and paper industry. The research team will work collaboratively with Port Hawkesbury Paper Mill who will provide thermomechanical pulp for experimentation.

“Although this research project was identified through our COVID research response initiative, it could also have a positive impact on the Nova Scotia forestry sector”, says Stefan Leslie, CEO of Research Nova Scotia. “As we pursue both a sustainable forestry industry and a response to the COVID pandemic, the research community is demonstrating its creativity and initiative.”

Note: This story originally appeared on the Research Nova Scotia website.